- Overview

- Product Description

Basic Info.

Model NO.

WF-SA

Material

Aluminum Plate

Type

Fusion Welding

Item

Customized Welding Part

Technics

Welding

Raw Material

Aluminum, Carbon Steel, Stainless Steel

Factory

Over 15 Years′ Experience

Price Range

1~5USD/PCS

Export Markets

Global

Model No

OEM Part

Delivery Time

Within Two Weeks After Receiving Your Prepayment

Place of Origin

Shandong(Mainland)

Packaging

Wood Case

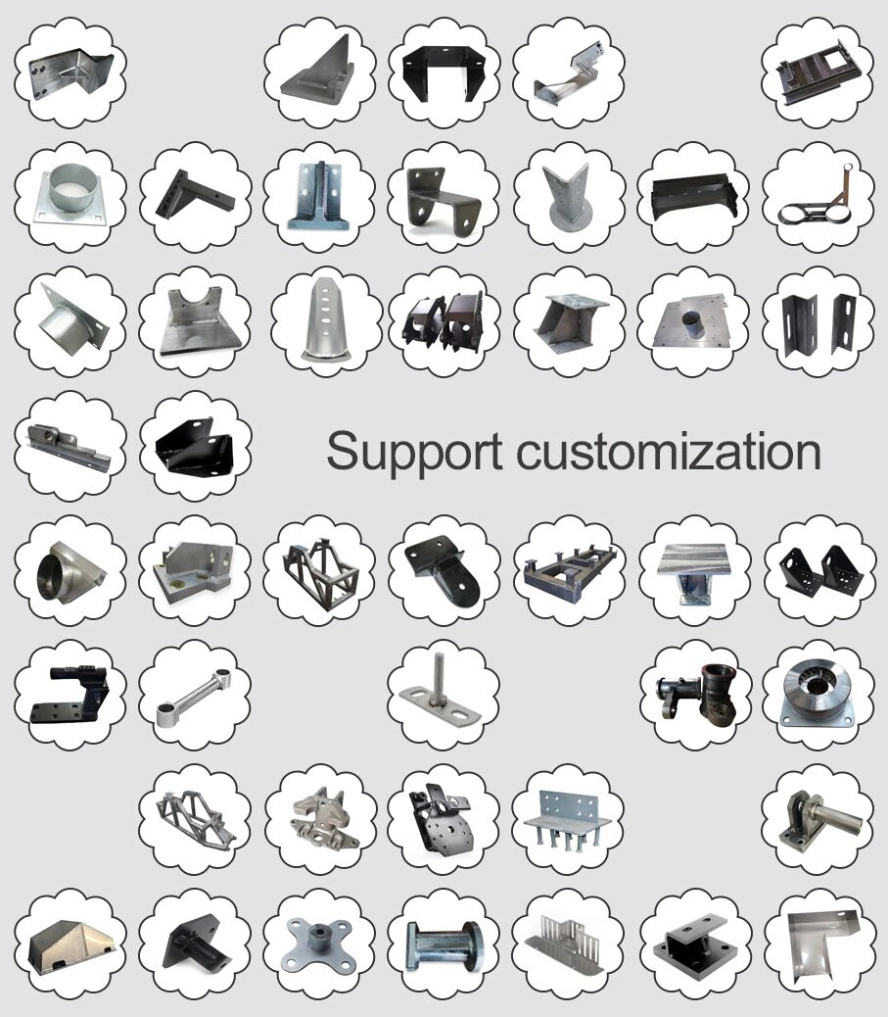

OEM Service

Yes

Custom Made

Yes

Logo Printing

Customized

MOQ

10-1000PCS

Free Sample

Yes

Transport Package

Plywood Box

Specification

CE, SGS

Trademark

ShengAo

Origin

Weifang, Shangdong, China

HS Code

87089910

Production Capacity

50000PCS/Month

Packaging & Delivery

Package Size

100.00cm * 90.00cm * 80.00cm

Package Gross Weight

100.000kg

Product Description

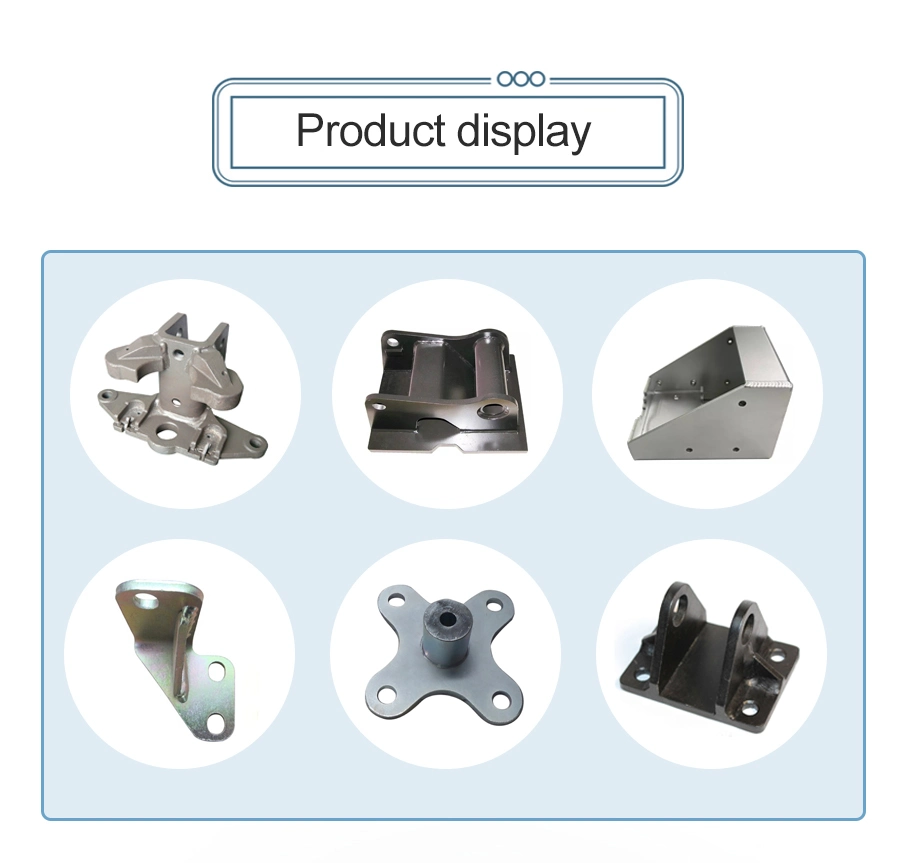

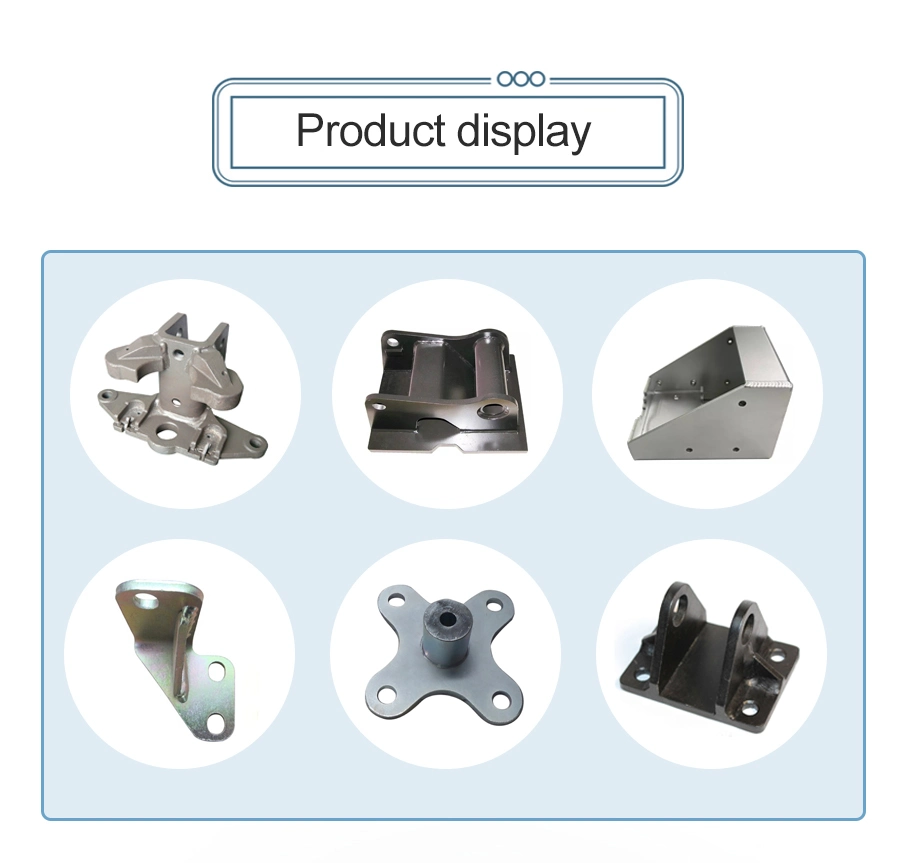

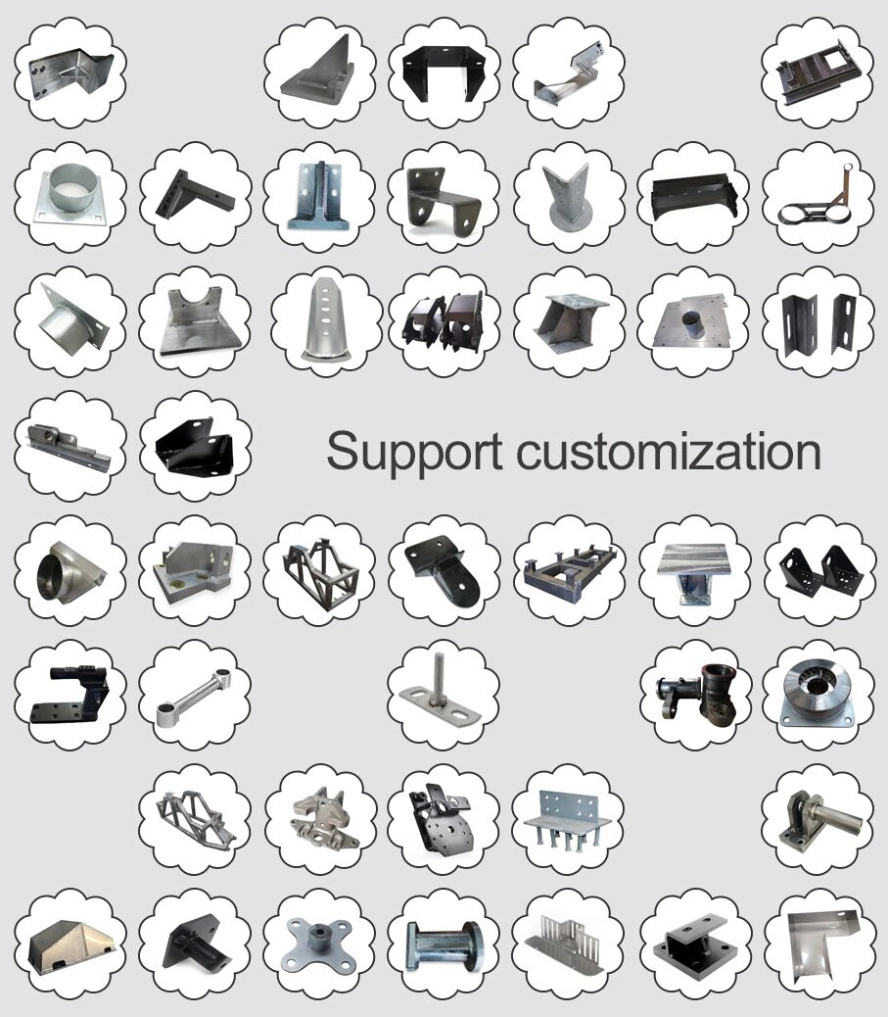

Customized Metal Spare Stamping and Processing Machinery Welding Part

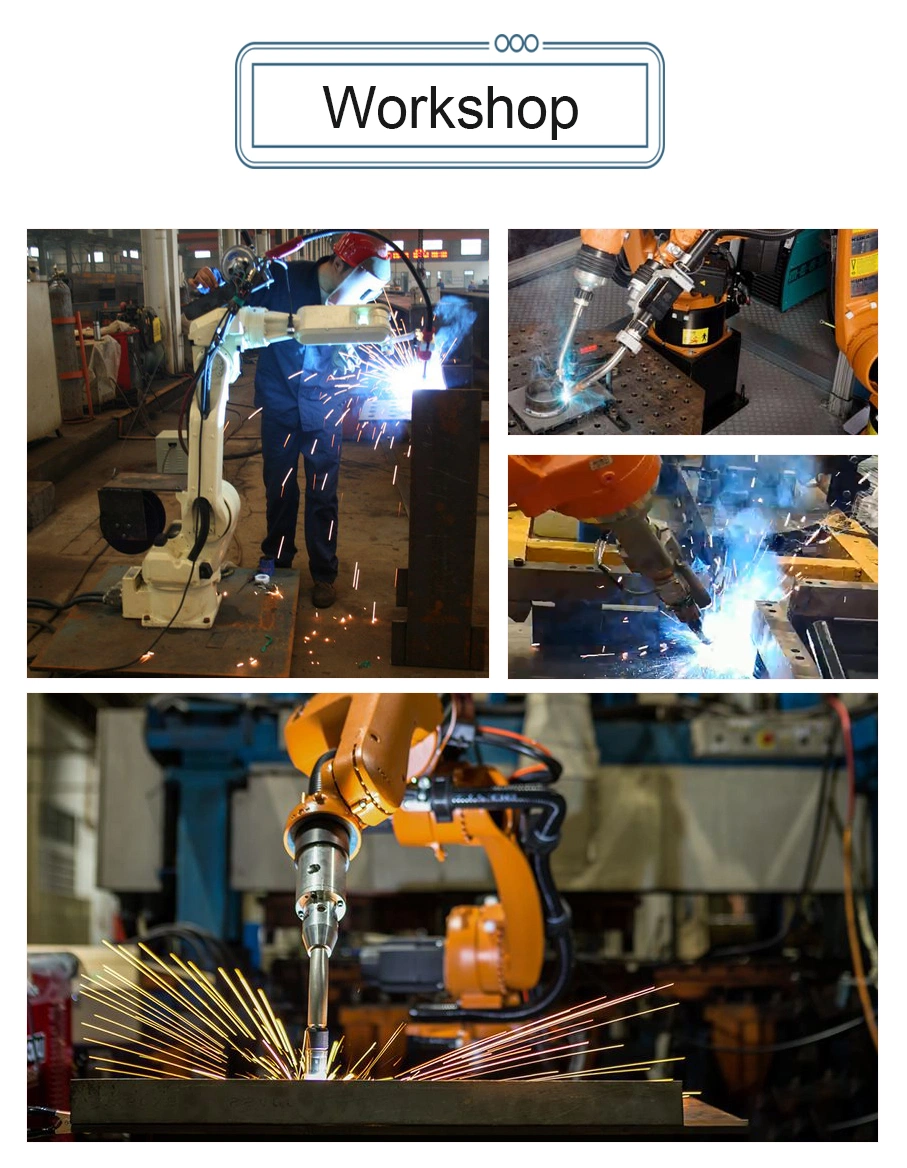

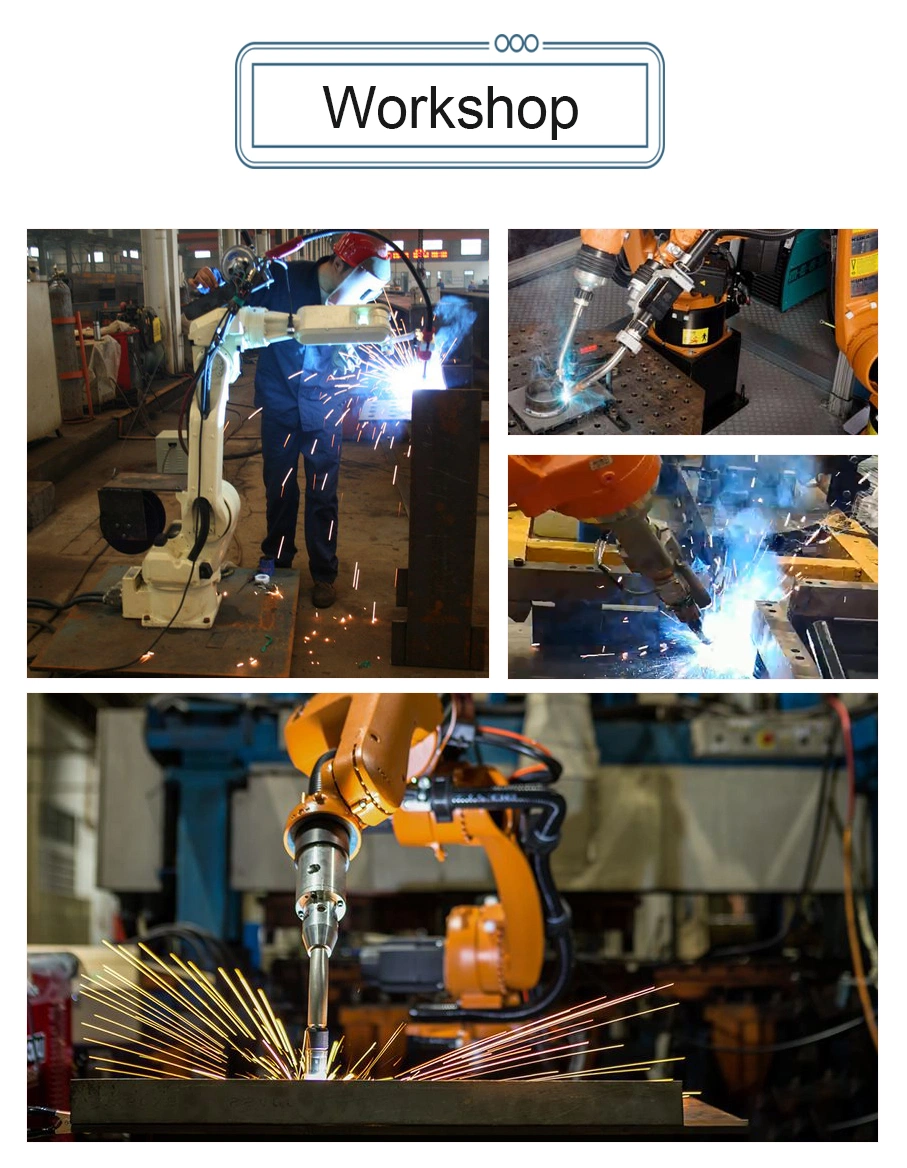

ISO 9001:2015 certified us utilizes ongoing employee training, automation, continuous process

improvement and innovation to maximize the quality, reliability, and cost-effectiveness of your

components.Parts are carefully examined throughout the production process at multiple quality

control checkpoints and all shipments are thoroughly tested and inspected before they are released

to your facility. As a result, our team has been able to consistently maintain a nearly 0% external

part reject rate that has enabled many of our customers to eliminate the costly and time eroding

process of inbound part inspection.

Each of our welders is qualified to one or more of the following specifications and/or codes:

AWS D1.1-Structural Welding Code-Steel

AWS D1.2-Structural Welding Code-Aluminum

AWS D1.3-Structural Welding Code-Sheet Steel

AWS D1.6-Structural Welding Code-Stainless Steel

AWS D14.3-Specification for Welding Earthmoving Construction and Agricultural Equipment

AWS D15.1-Railroad Welding Specification for Cars and Locomotives

EN 287-1-Qualification Test of Welders-Fusion welding-Part 1: Steels

DIN EN 15085-Railway Applications. Welding of Railway Vehicles and Components.

Customer specific welder qualifications.

We have a mature production process from raw materials to welding, surface treatment, etc. The

We have a mature production process from raw materials to welding, surface treatment, etc. The

materials include carbon steel, alloy steel, stainless steel, aluminum and cooper.

Our Services

Our Services

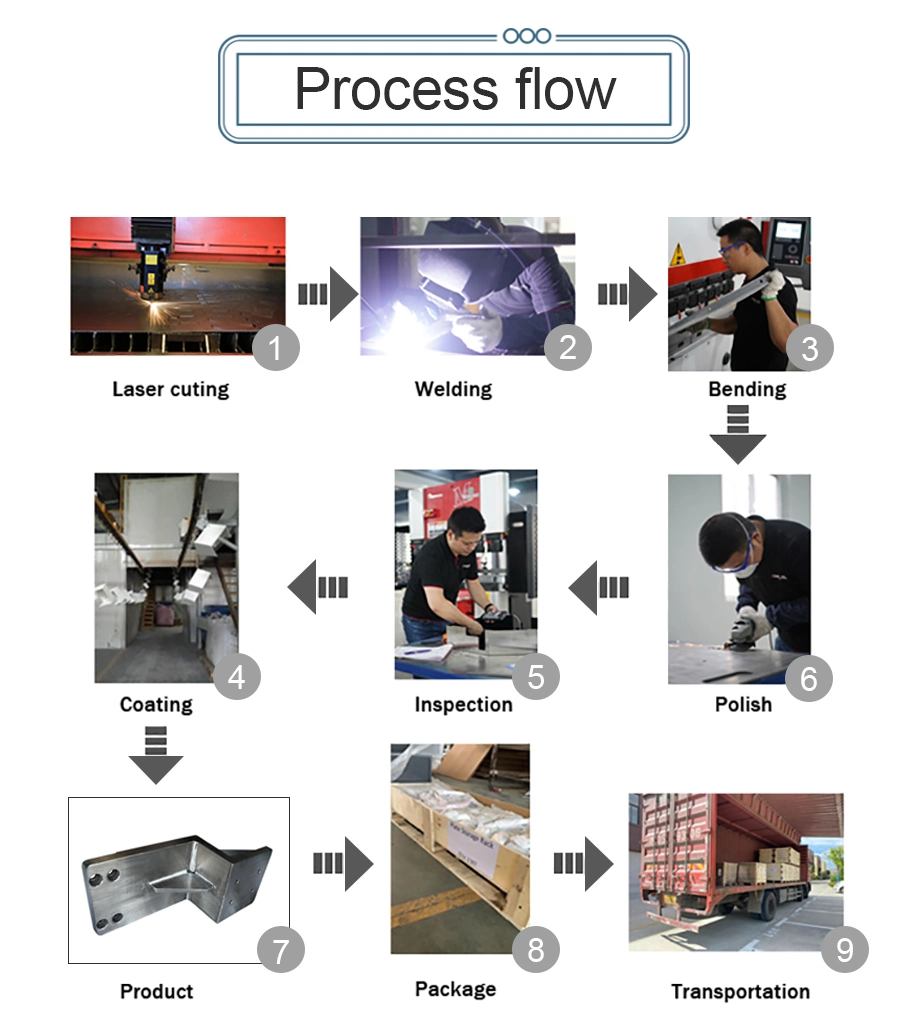

1.QC System:100% inspection on critical dimensions before shipment.

2.Drawing format:CAD ,PDF,DWG,etc.

3.Packaging: Standard package or rely on your request.

4.Payment Terms:30%T/T in advance, 70% balance before shipment.

| Design | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks |

| Material | Stainless steel,steel ,carbon steel, alloy steel,aluminum, etc 1. Stainless Steel: SS303, SS304, SS316, SUS420J2, etc 2. Steel: 12L14, 12L15, C45(AISI1045), etc 3. Carbon Steel: CH1T, ML08AL, 1010, 1035, 1045, etc 4. Alloy Steel: 10B21, 35ACR,40ACR, 40Cr, 35CrMn, etc 5. Aluminum or Aluminum Alloy: Al6061, Al6063, etc |

| Process | Cutting, stamping, deep drawing, bending, punching, threading, welding, tapping, riveting, grinding |

| Surface treatment | Hotgalvanized, zinc-plated, polishing, nickel-plated, chrome-plated, silver-plated, gold plated, imitation, gold plated, power coatingand as your demand |

| Manufacture | We use with advanced technology, unmatched skill, professional and advanced equipment size range from 15T-2500T, and experienced technicians to fit our customers requirements, like tooling manufacturing, stamping and surface treatment service |

| MQQ | Small order is accepted |

| Certification | ISO9001:2008 |

| After-sales Service | We will follow up every customer and solve all your problems satisfied after sale |

| Industry | These components are used in automobiles, bicycles, electric power, construction, engineering, household appliances, furniture, mechanical assembly, agricultural and horticultural machinery, OEM / ODM electronic products...... |

We have an individual team of well experienced QC staff and many high-educated technical

engineers who work throughout the whole manufacturing processes i. e., incoming raw materials,

production, and final output, to ensure that our products are of high-quality.

High quality products, reasonable price, prompt delivery, and superior service ensure marketing

competitiveness. Our factory has earned high reputation from customers.

We are looking forward to cooperating with you to forge a better future!

In order to ensure the quality of the orders,our independent QC members to carry out strict inspection

In order to ensure the quality of the orders,our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

Our Services

Our Services

1. Q: Why choose the Shengao product?

1. Q: Why choose the Shengao product?